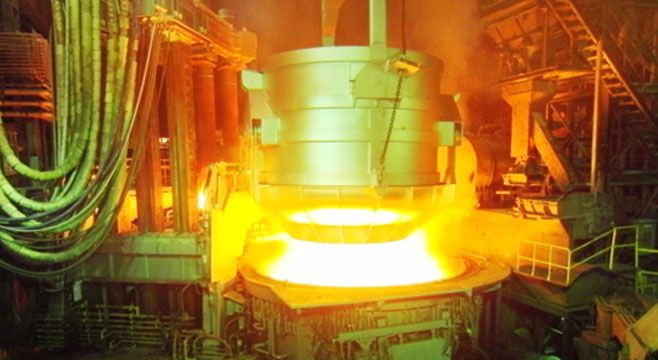

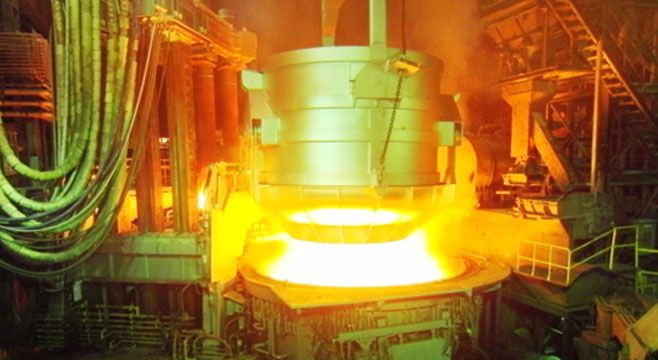

Electric Arc Furnace

Innovating NIKKO's Electric Arc Furnace through Unique Technology.

NIKKO achieved an optimal combination of furnace diameter, electrode PCD, and transformer capacity and strengthened the lifting and swing of the furnace roof, electrode lifting, and the tilting speed of the furnace body to promote efficient melting in NIKKO's unique electric arc furnace.

Furthermore, the design of each part has been made as simple as possible to improve maintainability.

In addition, the furnace volume was made one size larger than that with conventional models to reduce the scrap charging time and scrap pressing work.

The furnace is equipped with an aluminum conductor developed /designed by NIKKO which has the features long arcing by reducing the reactance of the secondary conductor on the furnace side.

Delivery example

Thailand / 70ton

Product

2017

- Capacity

- 70ton

- Max Capacity

- 80ton

- Model

- EBT

- Transformer

- 55/66MVA

- Reactor

- None

- Primary Voltage

- 35KV

- Max Secondary Voltage

- 870V

- Rated Secondary Voltage

- 660V

- Secondary Current

- 57.7kA

- Furnace Diameter

- 5700mm

- Tapping Method

- EBT

- Electrode Diameter

- 22Inch

- P.C.D

- 1,250mm

- Electrode Lifting

- Hydraulic

Vietnam / 80ton

Product

2012

- Capacity

- 80ton

- Max Capacity

- 125ton

- Model

- EBT

- Transformer

- 75/90MVA

- Reactor

- 10MVA

- Primary Voltage

- 35KV

- Max Secondary Voltage

- 1060V

- Rated Secondary Voltage

- 760V

- Secondary Current

- 57kA

- Furnace Diameter

- 6600㎜

- Tapping Method

- EBT

- Electrode Diameter

- 22inch

- P.C.D

- 1,300㎜

- Electrode Lifting

- Hydraulic

Taiwan / 80ton

Product

2010

- Capacity

- 80ton

- Max Capacity

- 125ton

- Model

- EBT

- Transformer

- 75/90MVA

- Reactor

- 10MVA

- Primary Voltage

- 24KV

- Max Secondary Voltage

- 1110V

- Rated Secondary Voltage

- 860V

- Secondary Current

- 60.42kA

- Furnace Diameter

- 6600㎜

- Tapping Method

- EBT

- Electrode Diameter

- 22inch

- P.C.D

- 1,300㎜

- Electrode Lifting

- Hydraulic

South Korea / 80ton

Product

2008

- Capacity

- 80ton

- Max Capacity

- 125ton

- Model

- EBT

- Transformer

- 70/84MVA

- Reactor

- 10MVA

- Primary Voltage

- 24KV

- Max Secondary Voltage

- 1100V

- Rated Secondary Voltage

- 770V

- Secondary Current

- 63kA

- Furnace Diameter

- 6600㎜

- Tapping Method

- EBT

- Electrode Diameter

- 24inch

- P.C.D

- 1,300㎜

- Electrode Lifting

- Hydraulic

South Korea / 100ton

Product

2012

- Capacity

- 93ton

- Max Capacity

- 113ton

- Model

- EBT

- Transformer

- 102MVA

- Reactor

- 10MVA

- Primary Voltage

- 22KV

- Max Secondary Voltage

- 1195V

- Rated Secondary Voltage

- 895V

- Secondary Current

- 65.8kA

- Furnace Diameter

- 6600㎜

- Tapping Method

- EBT

- Electrode Diameter

- 24inch

- P.C.D

- 1,300㎜

- Electrode Lifting

- Hydraulic

South Korea / 150ton

Product

2009

- Capacity

- 130ton

- Max Capacity

- 150ton

- Model

- EBT

- Transformer

- 99.5MVA

- Reactor

- None

- Primary Voltage

- 22KV

- Max Secondary Voltage

- 1150V

- Rated Secondary Voltage

- 910V

- Secondary Current

- 63.13kA

- Furnace Diameter

- 7000㎜

- Tapping Method

- EBT

- Electrode Diameter

- 22inch

- P.C.D

- 1,350㎜

- Electrode Lifting

- Hydraulic

South Korea / 30ton

Product

2004

- Capacity

- 30ton

- Max Capacity

- 40ton

- Model

- SPOUT

- Transformer

- 35/45MVA

- Reactor

- None

- Primary Voltage

- 24KV

- Max Secondary Voltage

- 700V

- Rated Secondary Voltage

- 525V

- Secondary Current

- 46kA

- Furnace Diameter

- 5000㎜

- Tapping Method

- Laundered Steel

- Electrode Diameter

- 20inch

- P.C.D

- 1,200㎜

- Electrode Lifting

- Hydraulic

Philippines / 60ton

Product

1999

- Capacity

- 55ton

- Max Capacity

- 65ton

- Model

- EBT

- Transformer

- 54MVA

- Reactor

- None

- Primary Voltage

- 24KV

- Max Secondary Voltage

- 750V

- Rated Secondary Voltage

- 570V

- Secondary Current

- 51.96kA

- Furnace Diameter

- 5600㎜

- Tapping Method

- EBT

- Electrode Diameter

- 20inch

- P.C.D

- 1,200㎜

- Electrode Lifting

- Electric

ProcessUntil an electric furnace is made

Step01

The steel manufacture factory foundation work

Briefly introducing the flow of Electric Arc Furnace construction work at Daehan Steel in Korea, 2007.

The beginning of work will be the foundation work of the steel melting shop.

Step02

Electric furnace setting place

Complete the foundation work of Electric Arc Furnace and start the construction work ...

Step03

The steel manufacture factory building is under construction

The melting shop building under construction.The building is gradually completed.

Step04

The Electric Furnace body

The furnace body qualified the criteria will be installed.

Step05

Preparations before aluminum conductor arm setting

Careful assembly and inspection work before installing the aluminum conductor arm.

Step06

Water-cooled furnace roof and furnace top elbow

The water-cooled furnace roof and furnace top elbow are installing on the electric furnace swivel device.

Step07

The electric furnace is completed

Electric furnace installation work completed!