Auxiliary Equipment for Electric Arc Furnace

NIKKO’s Electric Arc Furnace Auxiliary Equipment for High Efficiency and Energy and Power Saving.

NIKKO Electric Arc Furnace's auxiliary equipment realize higher performance with simple design.

Steel making equipment has still some more room to improve working environment and efficiency.

NIKKO pursues the innovation of EAF auxiliary equipment and components with higher technologies to meet working conditions.

Product introduction

Automated electrode connector (Joint Ace)

01Automated electrode connector (Joint Ace)

- Safe and quick electrode connection by remote control

- One person can connect the electrodes within two minutes by remote control. Electrodes can be connected securely with prescribed torque. It is possible to correspond for LF.

Water-cooled furnace roof and 4th hole elbow

02Water-cooled furnace roof and 4th hole elbow

- Light weight and long life

- The jacket type, pipe type, and energy-saving type can be designed. The lightweight design enables easy attachment and detachment.

Aluminum conducting arm

03Aluminum conducting arm

- Improving arc input power by minimizing three phases impedance unbalance

- This structure has a simple design to give top priority to maintainability. The arm is made of aluminum alloy to reduce the weight and improve the electrode responsiveness in ascent and descent, contributing to the improvement of the steel making unit consumption.

Water-cooled copper panel (NECT)

04Water-cooled copper panel (NECT)

- Great reduction of refractory unit consumption

- Steel and pipe materials are employed for the upper part of the furnace wall and the lower slag line is made of pure copper. Near the slag line, Super NECT (made of pure copper forged) is employed to realize long life.

SUPER NECT

05SUPER NECT

- The panel which is made by pure copper, forging, and resist the high heat load

- To put near slag line area instead of refractory. Withstanding wild heat attack Long life.

ACT

06ACT

- Blow epoch-making oxygen letting effectively utilize the combustion efficiency in the furnace to the maximum; a panel

- Achieving active chemical reaction (C + O2) in the furnace by blowing oxygen through the hole of slagline copperpanel. Possible to make uniform melting scrap.

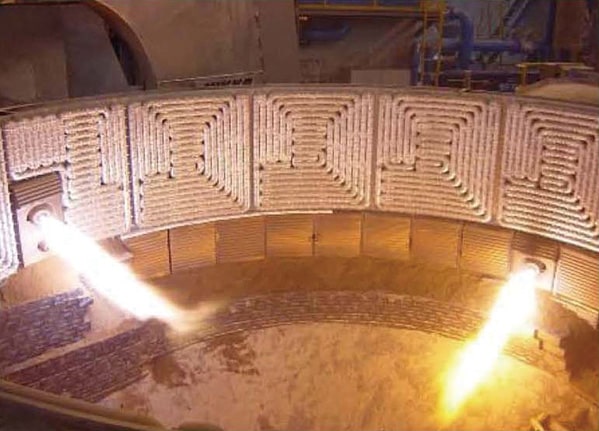

Jet burners(JB)

07Jet burners(JB)

- NIKKO is the pioneer of Oxy-Fuel Burner System for EAF.

- Various type of burners are available to meet EAF operation such as FA burner, EBT burner and Slag door burner. NIKKO's Hybrid Burner is achieving good performance for scrap melting and cutting, heating up of molten steel by the effect of slag forming. Possible to select the fuel such as liquid fuel (Kerosine) or gas (LNG)

FA Burner

08FA Burner

- New Burner with Angled Tip

- By angling the nozzle at the burner tip, the flame is directed at a sharp angle towards the molten surface. Additionally, by rotating the main body, it is possible to adjust the direction of the flame.

Door burner

09Door burner

- Preventing furnace temperature drop by fully closing the work door

- By heating the scrap to a red-hot state and cutting it, the cold spot in front of the furnace is eliminated. This eliminates any residual material in front of the work door and contributes to uniform melting.

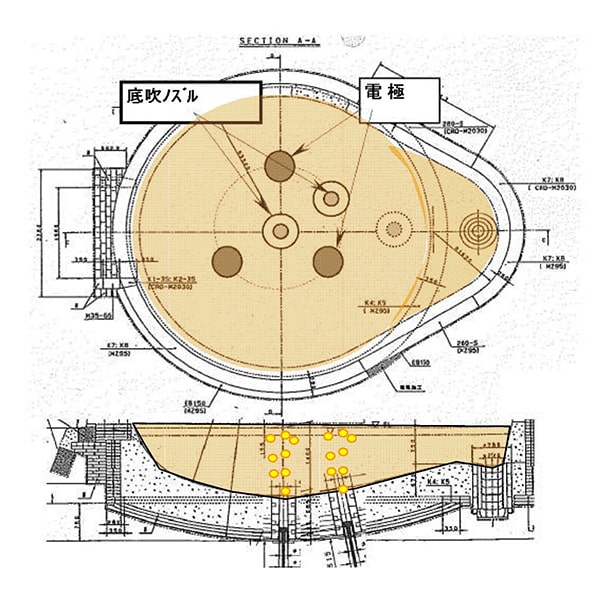

BOTTOM BUBBLING SYSTEM

10BOTTOM BUBBLING SYSTEM

- To achieve uniform melting by stirring molten steel

- To make “active agitation of molten steel” in the furnace. Possible to make uniform scrap melting.